LA BRIDOIRE BELTS

SEUL FABRICANT FRANCAIS DE BANDE Z POUR LES FOURS DE BISCUITERIE

La société La Bridoire Belts vient d’acquérir la division de tapis tréfilés, la fameuse bande Z.

Depuis plus de 60 ans ce type de bande est produite et vendue pour répondre aux besoins spécifiques des fours de biscuiteries.

Les tapis tréfilés appelés également bandes sont conçus pour offrir longévité et facilité d’entretien. Ces tapis sont tréfilés à partir de fils d’acier et peuvent être livrés en largeur de plus de 1,5 mètres et en longueur jusque 300 mètres. Choisir une bande Z fabriquée en France est l’assurance d’acquérir un produit de qualité.

DU CHANGEMENT DANS LA SOCIETE

Le leader mondial en tapis tréfilés, pour fours de biscuiterie change de direction & de nom (avril 2023).

« Agrati la bridoire » fabricant français de bandes Z depuis 1919, devient donc « la Bridoire Belts ».

La société LTL Holding, (située à Crest dans la Drôme), composée des sociétés TISSMETAL et MC&I – Métal Concept & Industrie, est leader du secteur de la maille métallique en France depuis plus de 100 ans.

HISTORIQUE DE LA SOCIETE

La première société, la « Maison Mage », a été créée à Lyon en 1840 pour produire des tapis métalliques.

A la fin du 19 ème siècle, la société se déplace à La Bridoire afin d’utiliser la force motrice du torrent issus du Lac d’Aiguebelette. La nouvelle société prend le nom du successeur : «Paul Tourasse & Cie ».

Après la première guerre mondiale, une nouvelle société est créée, nommée « Produits Tréfilés de la Bridoire ». Elle provient de la fusion des Établissements Tourasse avec la fabrique de visserie de Mr Lévin, venue à La Bridoire afin de bénéficier des tarifs avantageux sur l’électricité offerts par la ville. Depuis lors, les deux fabrications, tapis et visserie, cohabitent à La Bridoire. La société PTB livre des tapis pour convoyeurs de mines et des grillages pour les marchés internationaux.

NAISSANCE DE LA BANDE Z

Dans les années 60, la fameuse bande «Z» est créée pour les biscuiteries industrielles.

Elle répond aux besoins en termes de résistance, légèreté, faible inertie thermique et une circulation optimisée.

Ces caractéristiques et l’expérience acquise la positionnent rapidement comme le leader mondial pour les fours de biscuiteries.

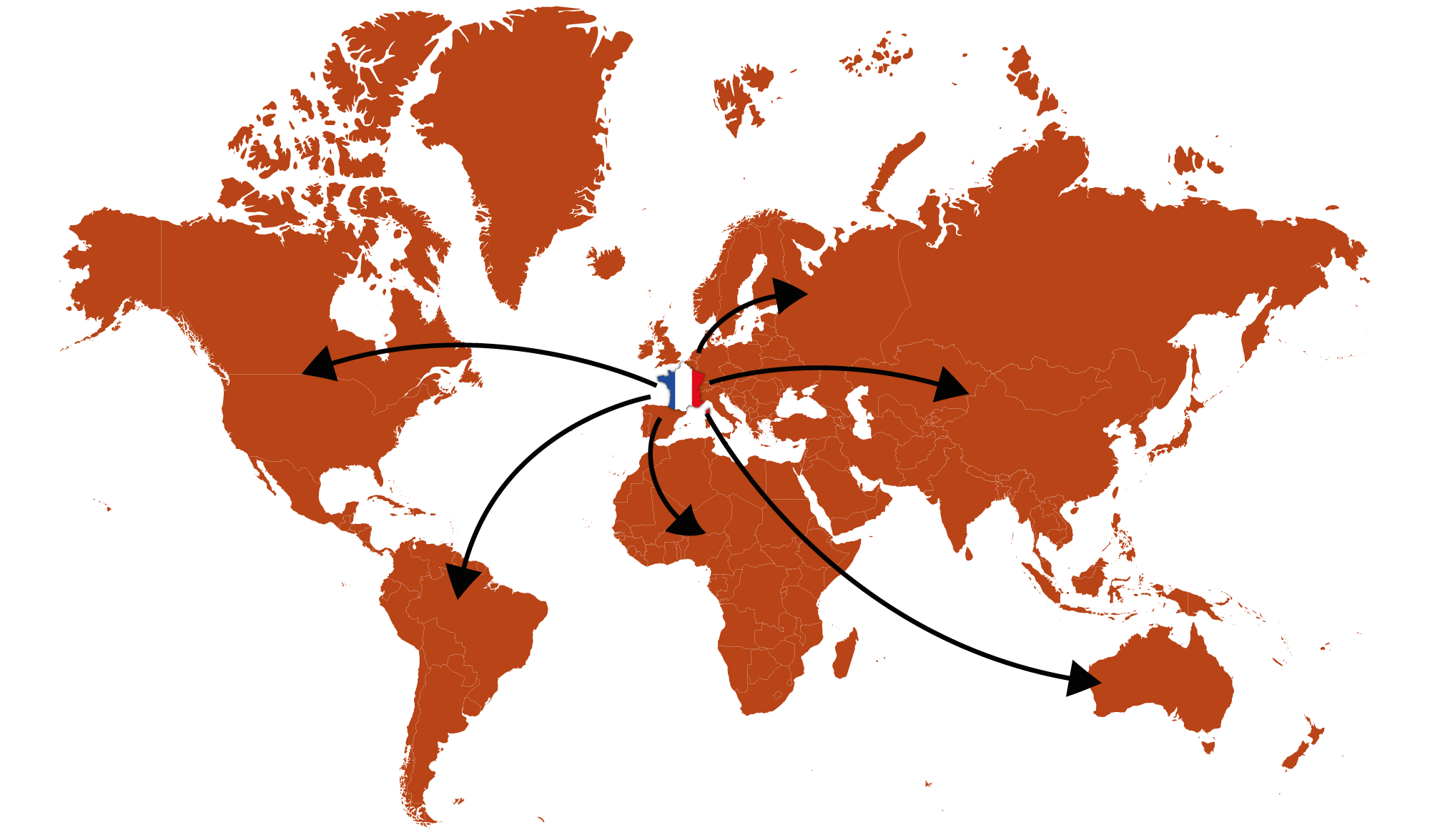

C’est donc dans une logique de déploiement industriel spécialisé dans la maille métallique que La société LT Holding, LEADER FRANÇAIS VIENT DE COMPLÉTER sa palette de prestations avec Les bandes métalliques pour fours, qui sont livrées à destination de biscuiteries partout dans le monde, directement de l’usine de Savoie.

La société LA BRIDOIRE BELTS rachète l’activité de bandes Z en avril 2023.

GAMME DE PRODUITS

Aujourd’hui les bandes métalliques pour fours sont livrées à destination de biscuiteries partout dans le monde, directement de l’usine de Savoie ou au travers d’un réseau de distributeurs agréés.

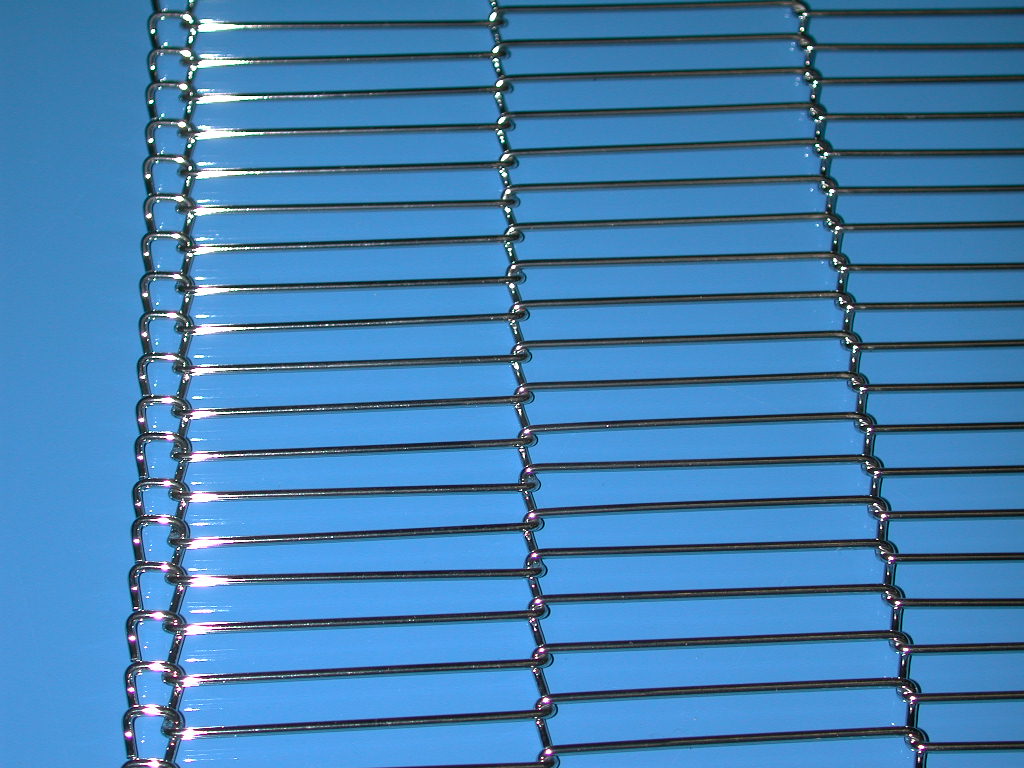

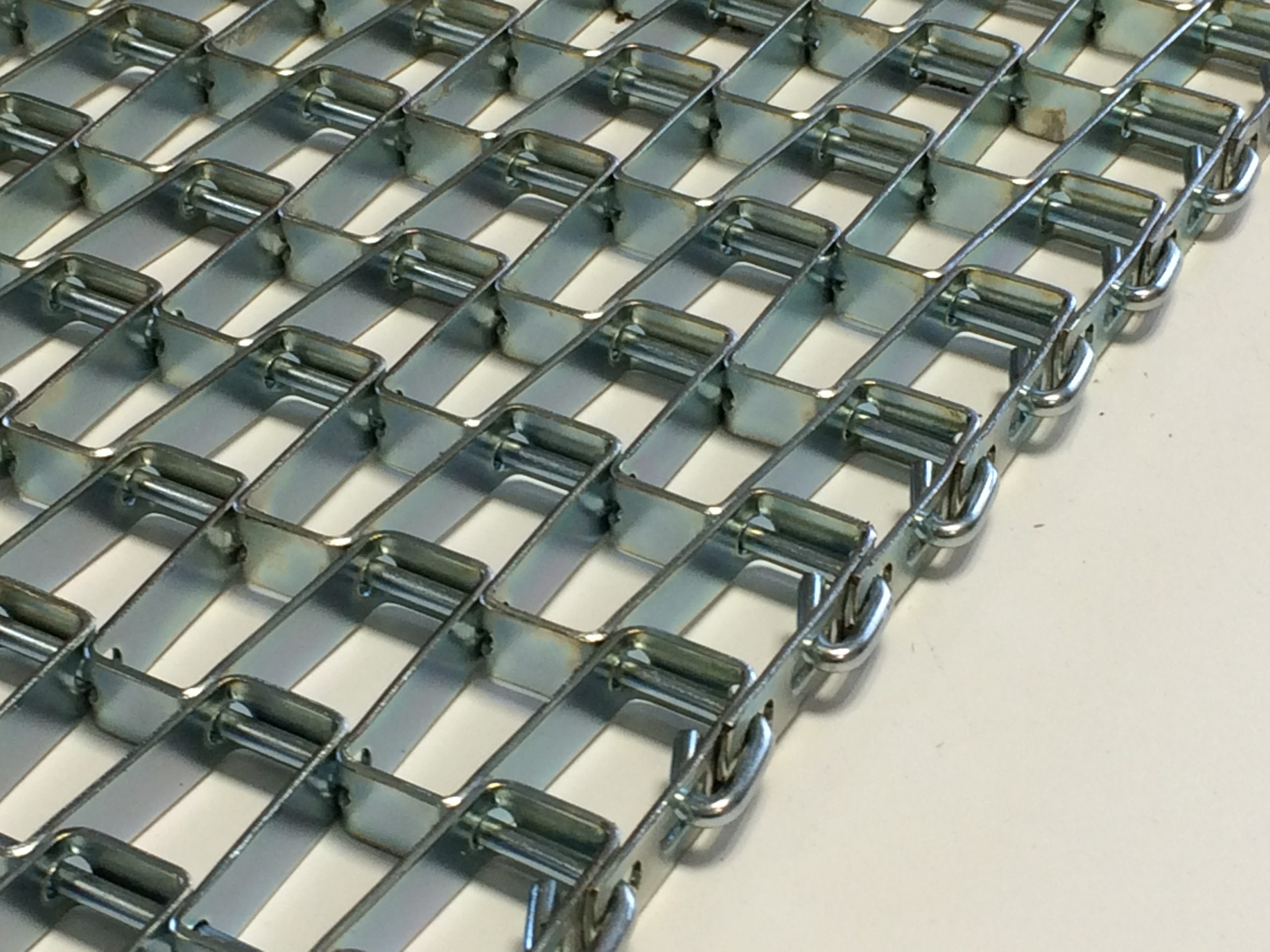

Z47

le tapis réputé pour les gros équipements à haut rendement. (vitesse jusqu’à 30m/min). L’espace entre les mailles permet une excellente circulation d’air pendant la cuisson.

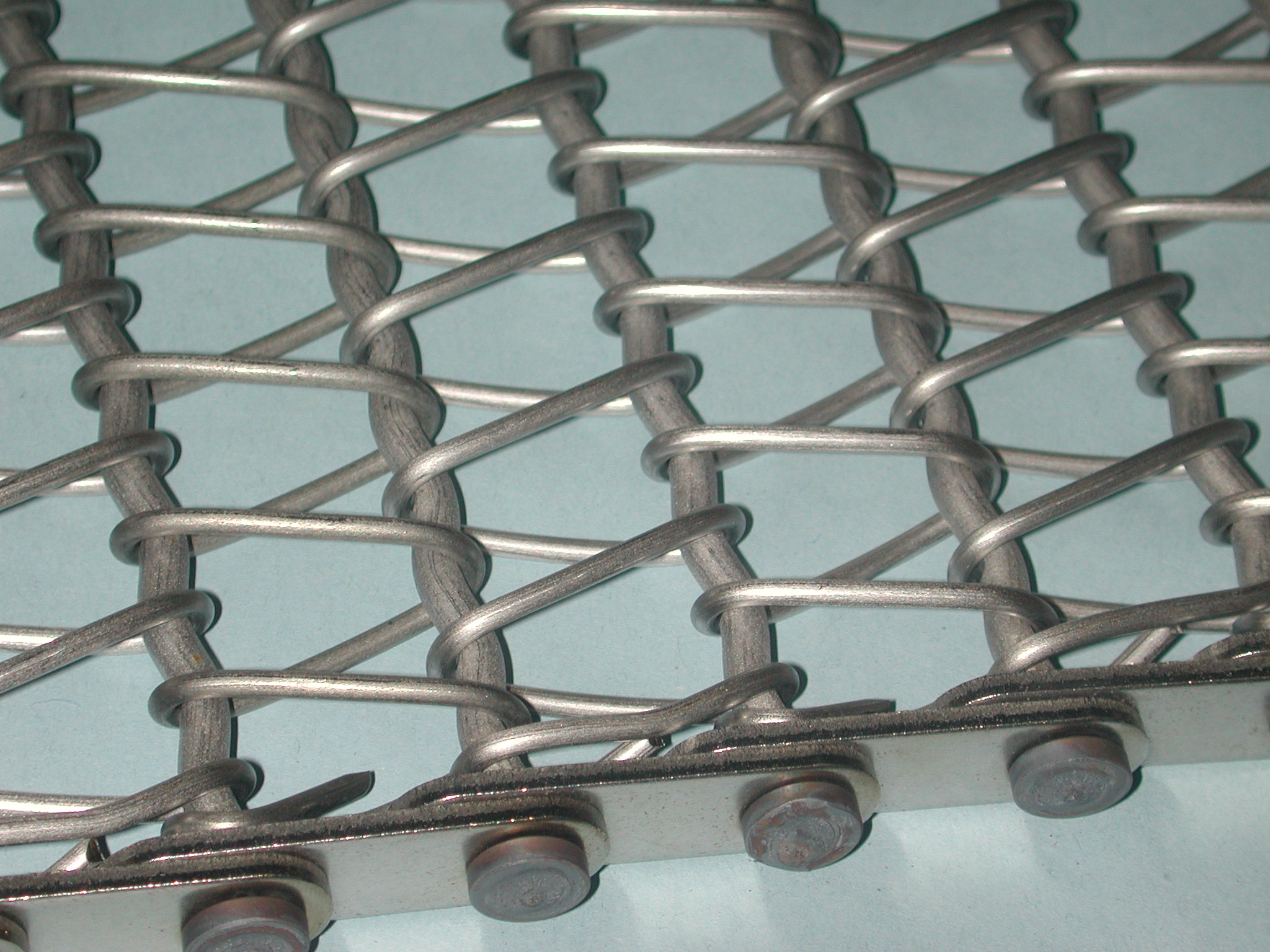

Z47R

est une version de la bande Z47 possédant une résistance accrue contre le déchirement pour une meilleure longévité du tapis ou un usage intensif.

Par contre son utilisation nécessite une température de cuisson plus élevée qu’avec la Z47.

GAMME DE PRODUITS

Aujourd’hui les bandes métalliques pour fours sont livrées à destination de biscuiteries partout dans le monde, directement de l’usine de Savoie ou au travers d’un réseau de distributeurs agréés.

Z47

le tapis réputé pour les gros équipements à haut rendement. (vitesse jusqu’à 30m/min). L’espace entre les mailles permet une excellente circulation d’air pendant la cuisson.

Z47R

est une version de la bande Z47 possédant une résistance accrue contre le déchirement pour une meilleure longévité du tapis ou un usage intensif.

Par contre son utilisation nécessite une température de cuisson plus élevée qu’avec la Z47.

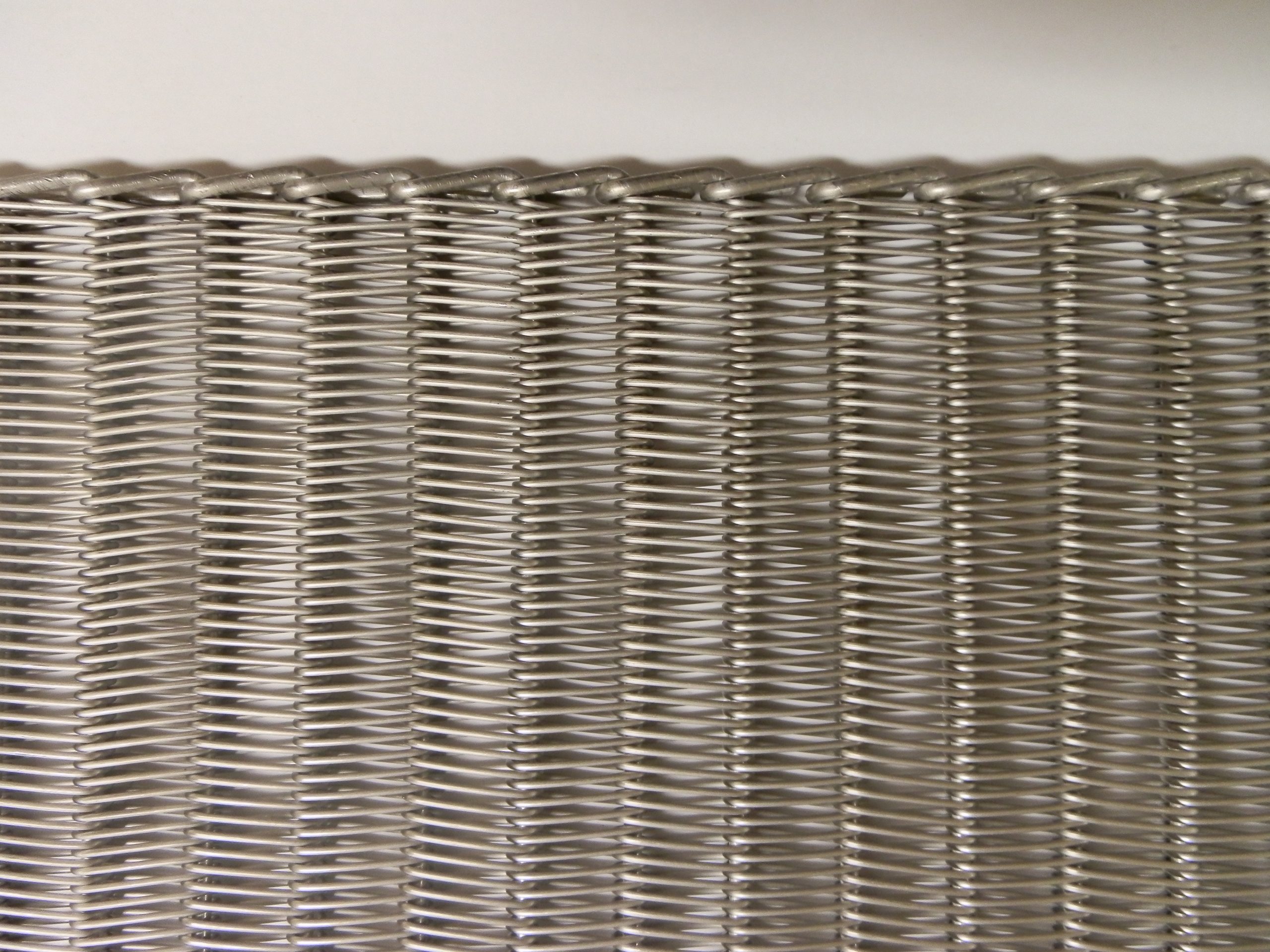

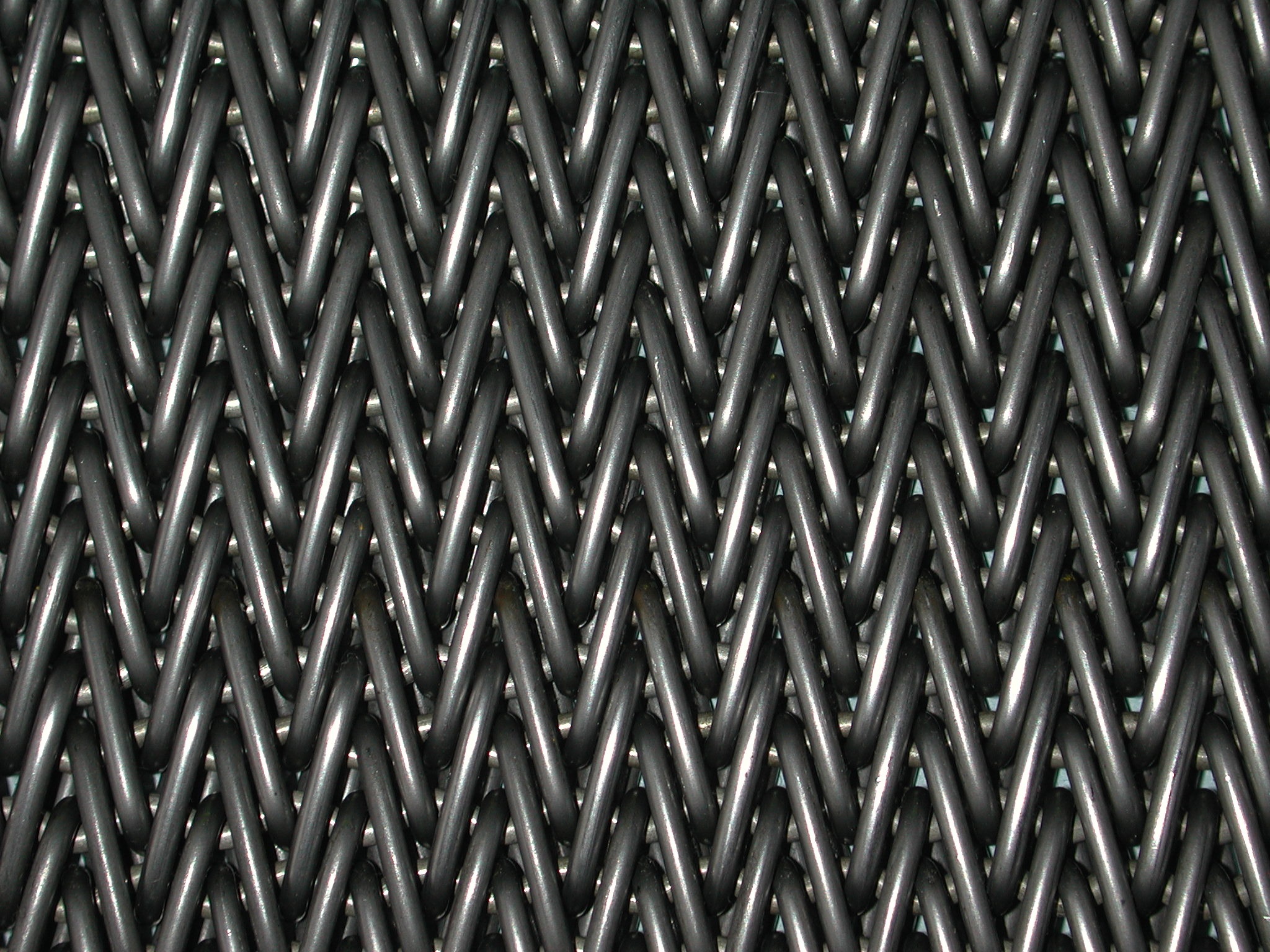

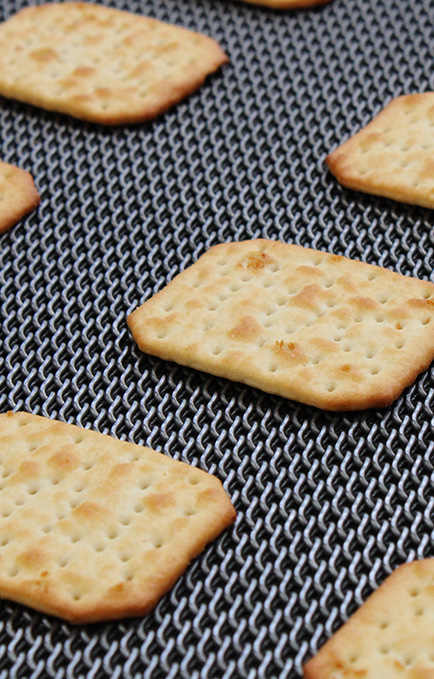

Z28

permet de réduire la température du four en vue d’économies. Le diamètre des fils est réduit, les hautes températures sont donc à éviter.

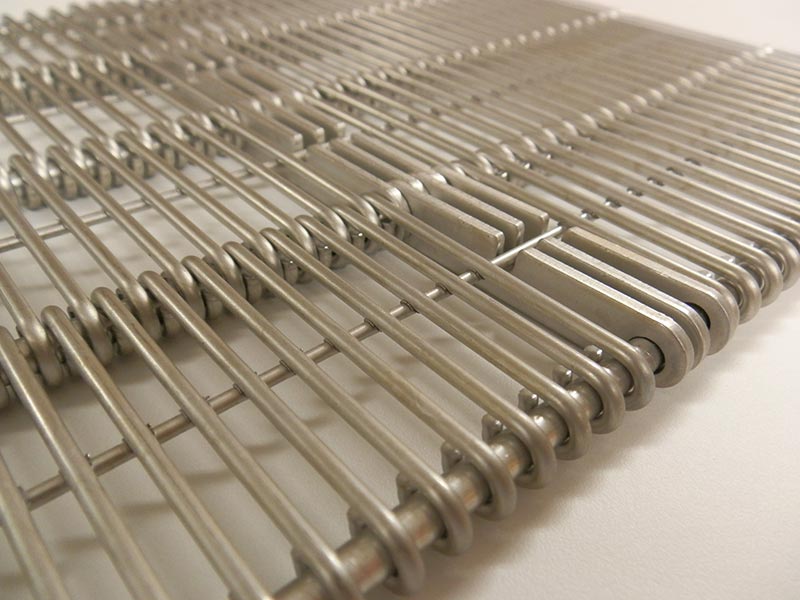

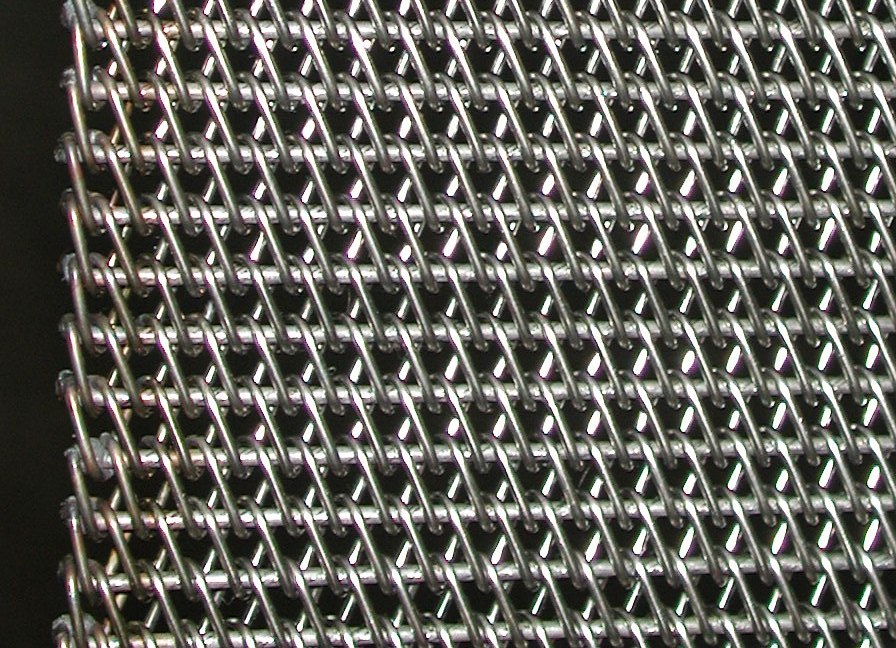

Z48

spécialement étudiée pour la cuisson des biscottes et biscuits durs, la bande Z48 possède des mailles larges pour une circulation d’air optimisée.

CARACTERISTIQUES DES TAPIS

Nous proposons principalement 4 sortes de tapis (ou bandes Z) en fonction des caractéristiques techniques requises :

Poids, taille, épaisseur, inertie thermique, circulation de l’air au travers des mailles.

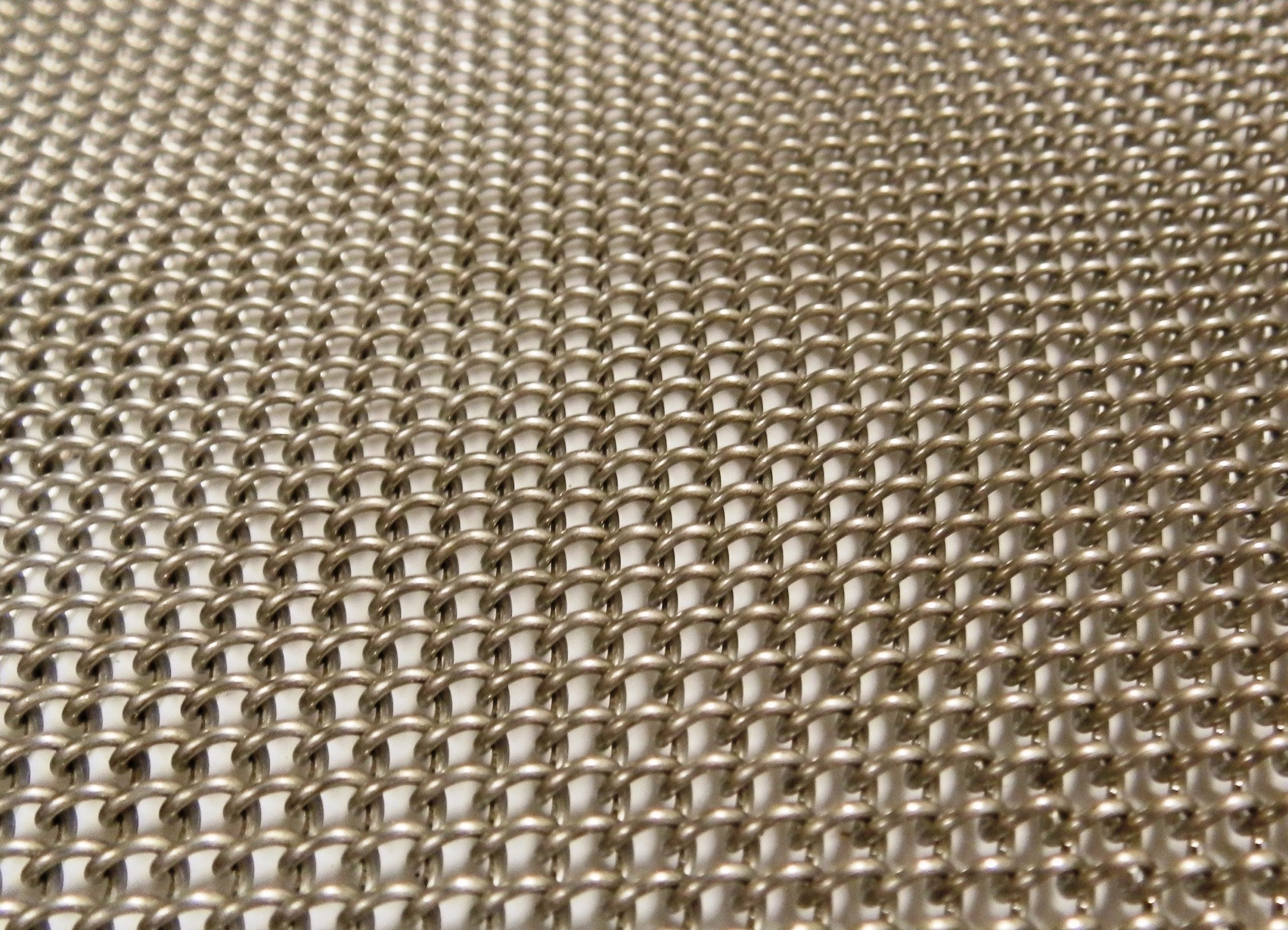

Toutes les bandes Z sont réalisées suivant des critères de qualité stricts. Les bordures sont bouclées pour rendre le tapis plus flexible et améliorer le contact avec les tambours d’entrainement même de faible diamètre. La finition des bordures réduit les risques d’endommagement du tapis par les guides latéraux ou les lames des fours.

La méthode de fabrication assure un parfait alignement du fil et un espace plus large entre les mailles pour une résistance équivalente. Cela est essentiel pour permettre à nos clients une cuisson rapide et uniforme dans leurs fours tout en permettant de garder la bande Z propre.

Bords bouclés (épaisseur +8/10 mm)

• Augmente la durée de vie des bords (plus résistant aux frottement)

• Evite les vibrations lors de contact contre d’autre partie métallique

• Protection de l’homme lors de la manutention

DONNEES TECHNIQUES (DIMENSIONS)

Mise en route

Avant de mettre en marche le convoyeur, découper la bande Z aux bonnes dimensions en laissant une course suffisante pour le tambour d’entrainement. La tension de la bande Z doit être suffisante pour éviter que le tapis ne glisse en dehors du tambour d’entraînement. Merci de bien vérifier le sens de rotation (voir la flèche peinte).

Recommandations

Il est conseillé de changer le tapis tous les 3 ans lorsqu’il est utilisé en production normale. En cas d’utilisation plus intensive ou de fours à très hautes températures, l’espérance de vie est notablement réduite.

Il est important de noter que chaque tapis est produit suivant le besoin du client (notamment la largeur et la longueur). Le délai normal de livraison est donc compris entre 6 à 10 semaines. Il faut donc le prévoir dans la maintenance préventive.

AUTRES PRODUITS

La Bridoire Belts est expert dans la production de son produit : « Les bandes Z ». Mais notre société propose aussi, d’autres sortes de tapis métalliques.

Venez découvrir l’ensemble de nos produits.

NOS CLIENTS

Des clients partout dans le monde

Nous commercialisons nos bandes métalliques Z pour four, en France et à l’international. Fort de notre expérience et de notre savoir, nous produisons de la maille métallique depuis près de 100 ans. Notre conception est réalisée en France, plus précisément en Savoie.

Des clients partout dans le monde

Nous commercialisons nos tapis et bandes métalliques pour four en France et à l’international. Fort de notre expérience et de notre savoir, nous produisons de la maille métallique depuis près de 100 ans. Notre conception est réalisée en France, plus précisément en Savoie.