LA BRIDOIRE BELTS

THE ONLY FRENCH MANUFACTURER OF Z BELTS FOR BISCUIT OVENS

The company La Bridoire Belts has just acquired the wire belt division, the famous Z belt. For over 60 years, this type of belt has been produced and sold to meet the specific needs of biscuit ovens.

Wire belts are designed to offer longevity and ease of maintenance. These belts are made of steel wire and can be delivered in widths of over 1.5 metres and lengths of up to 300 metres. Choosing a Z belt made in France is a guarantee of purchasing a quality product.

CHANGE IN THE COMPANY

The world leader in wire belts for biscuit ovens is changing its management and name (April 2023). “Agrati La Bridoire”, the French manufacturer of Z belts since 1919, is therefore becoming “La Bridoire Belts”.

The company LTL Holding, (located in Crest in the Drôme), made up of the companies TISSMETAL and MCCI – Métal Concept C Industrie, has been the leader in the metal mesh sector in France for over 100 years.

HISTORY OF THE COMPANY

The first company “Maison Mage”, was created in Lyon in 1840 to produce metal belts.

At the end of the 19th century, the company moved to La Bridoire in order to use the driving force of the torrent from Lake Aiguebelette. The new company took the name of the successor : «Paul Tourasse & Cie ».

After the First World War, a new company was created, called “Produits Tréfilés de la Bridoire”. It came from the merger of Établissements Tourasse with the screw factory of Mr Lévin, who came to La Bridoire to benefit from the advantageous electricity rates offered by the city. Since then, the two manufacturing companies, for belts and screws, have coexisted in La Bridoire. The company PTB supplies belts for mine conveyors and wire mesh for international markets.

BIRTH OF THE Z BELT

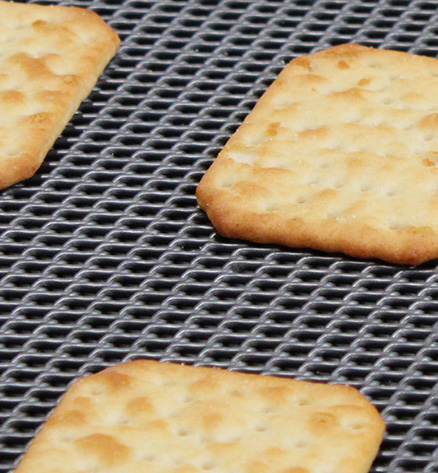

In the 1960s, the famous Z belt was created for industrial biscuit factories. It responds to needs in terms of resistance, lightness, low thermal inertia and optimised circulation.

These characteristics and experience quickly positioned it as the world leader for biscuit ovens.

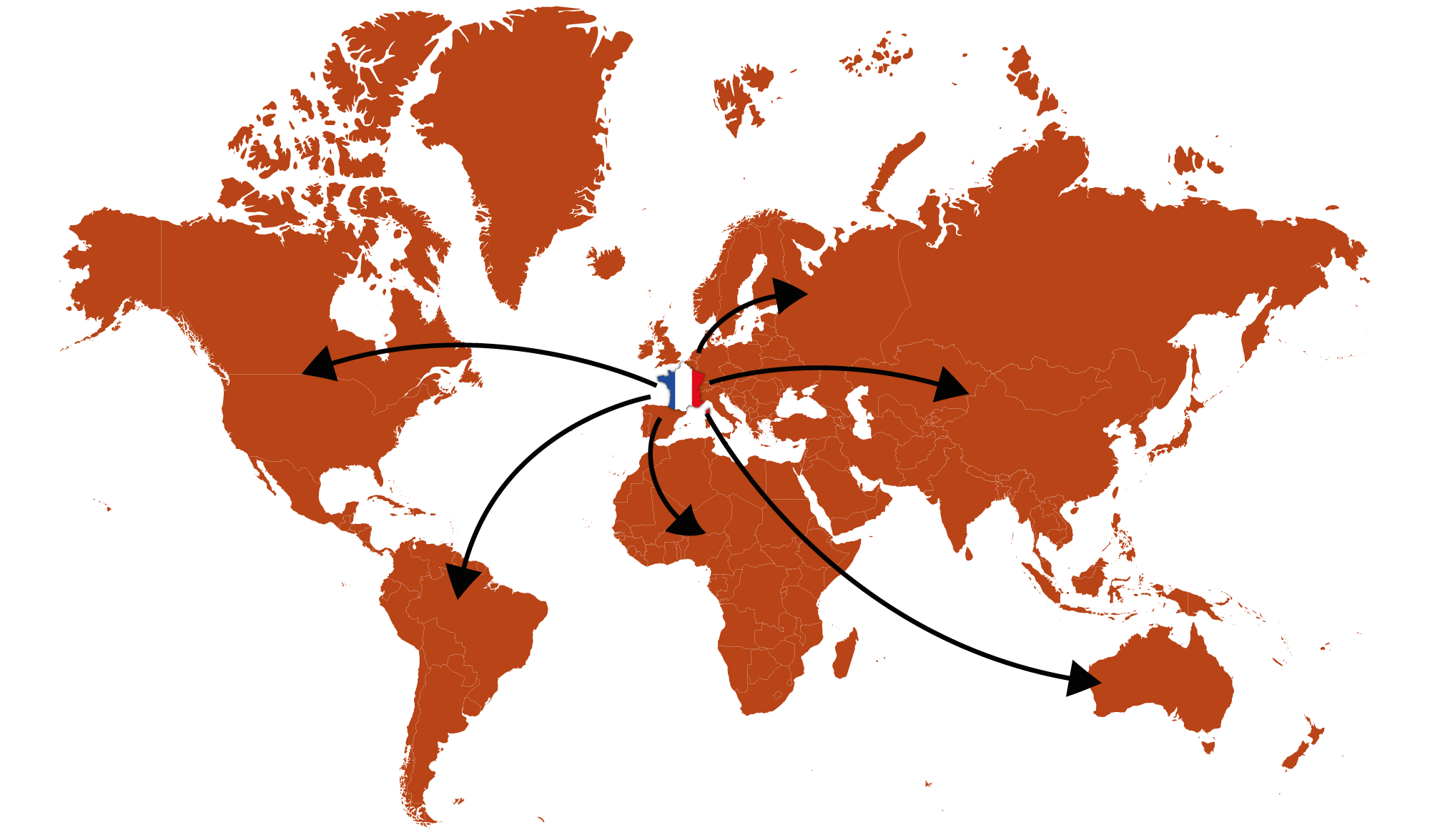

It is therefore in the context of industrial deployment specialised in metal mesh that the company LTL Holding, FRENCH LEADER, HAS JUST COMPLETED its range of services with metal belts for ovens, which are delivered to biscuit factories all over the world, directly from the Savoie factory.

The company LA BRIDOIRE BELTS purchased the Z belt business in April 2023.

RANGE OF PRODUCTS

Today, metal belts for ovens are delivered to biscuit factories all over the world, directly from the Savoie factory or through a network of approved distributors.

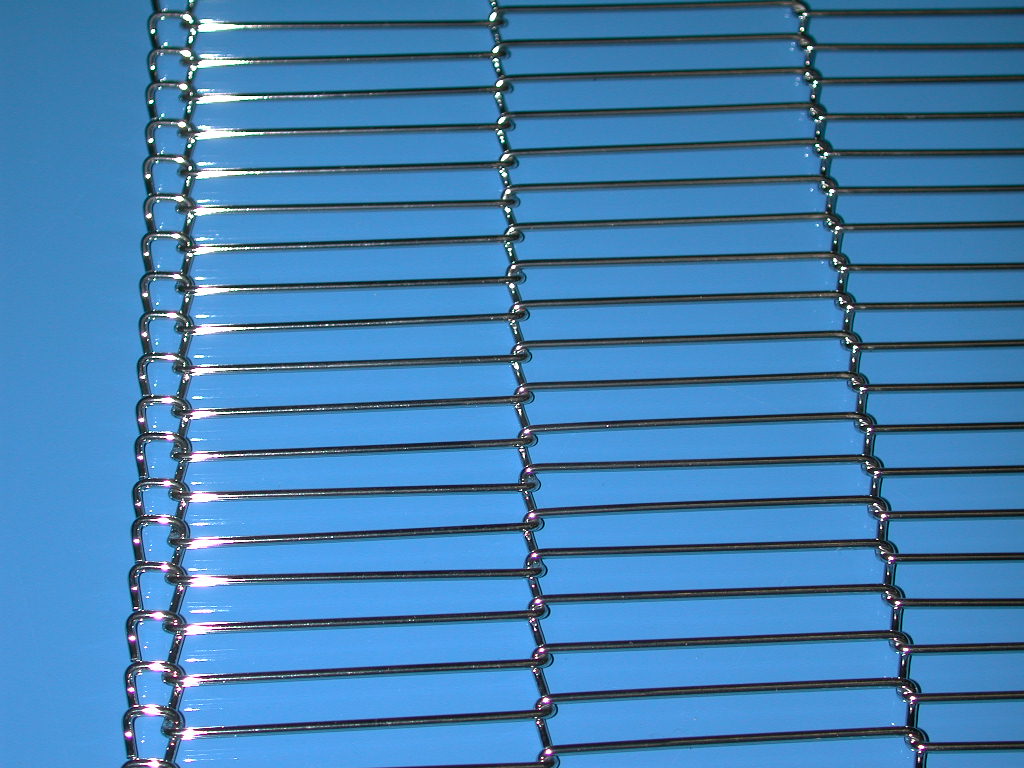

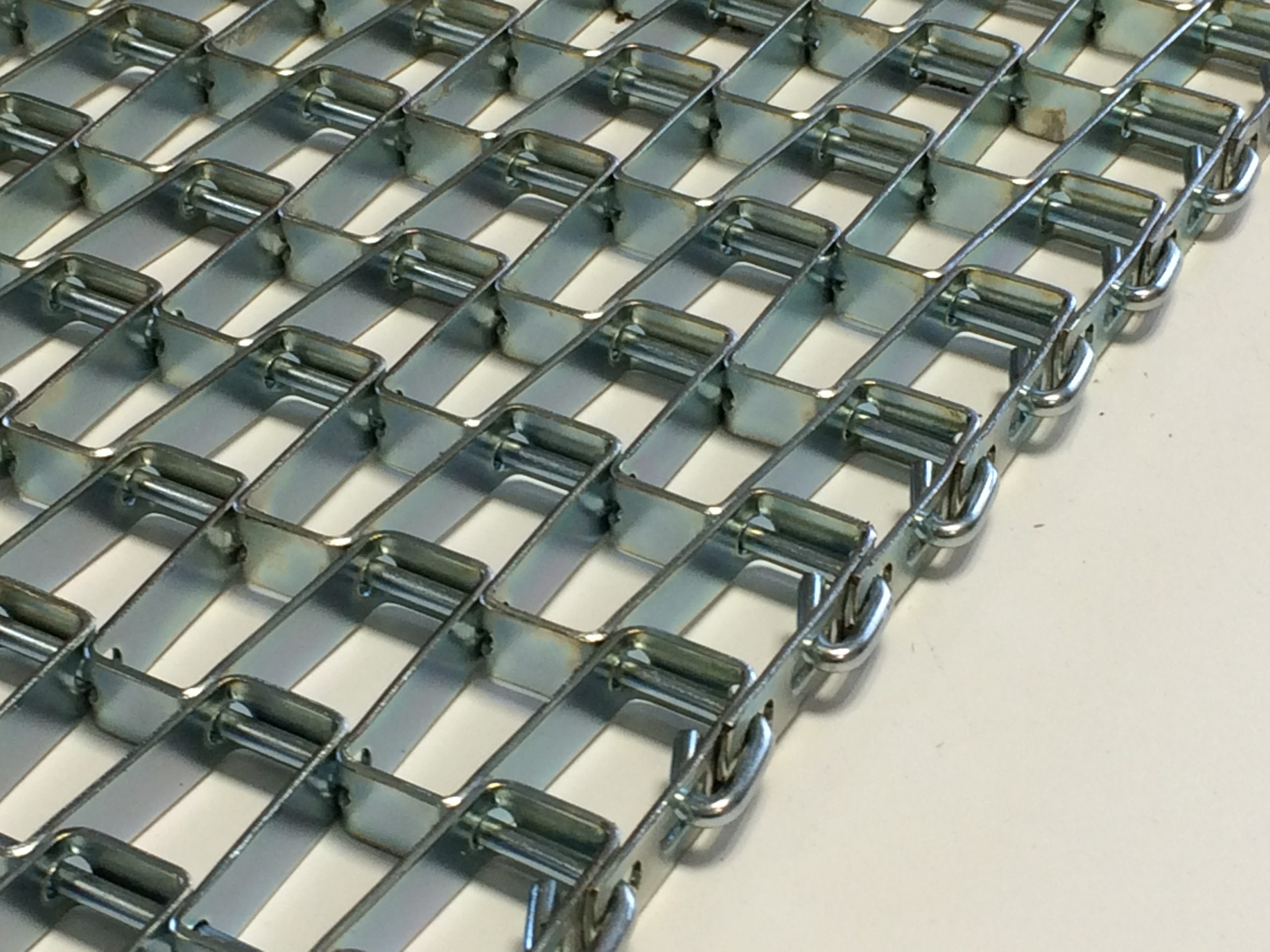

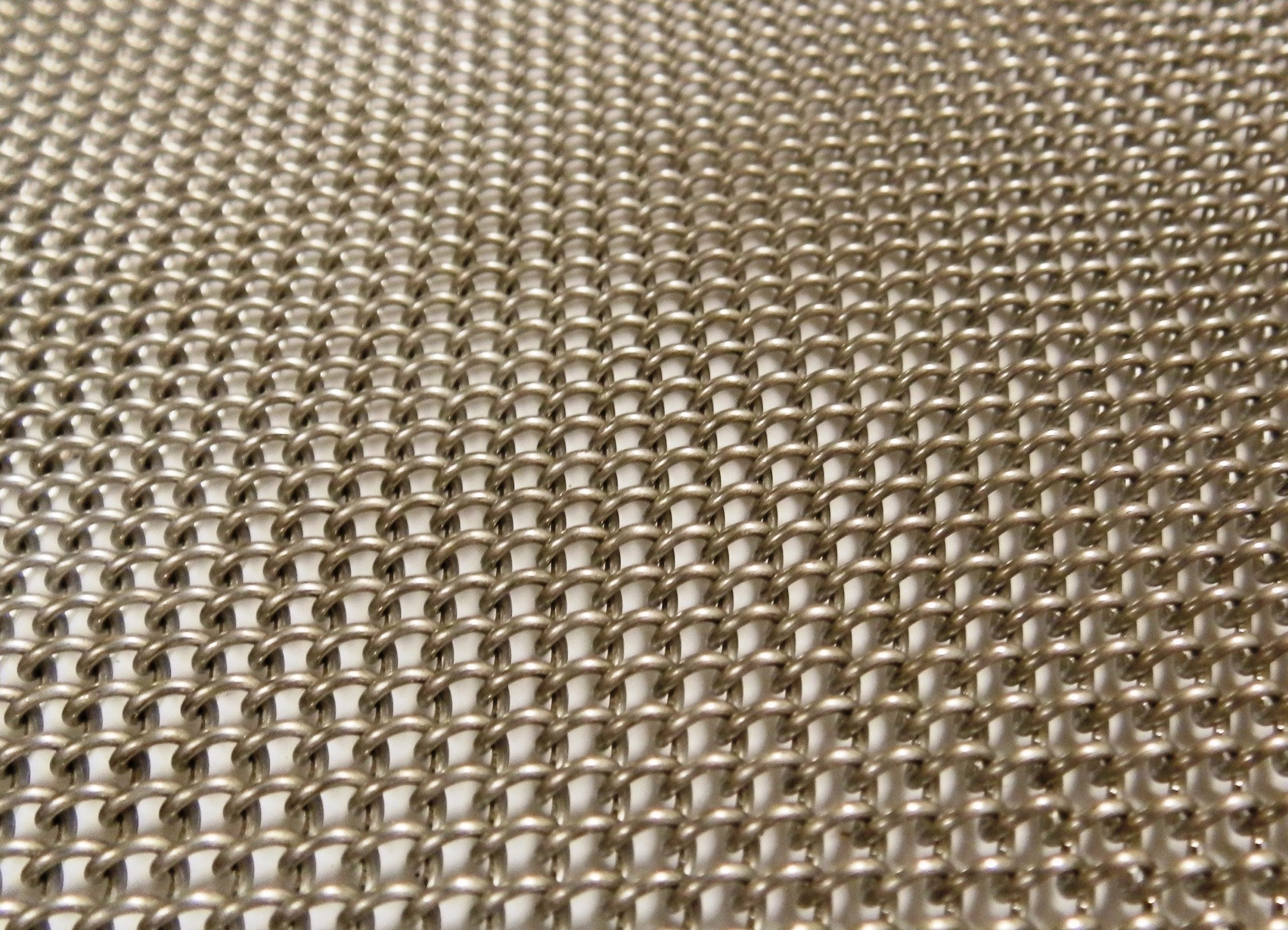

Z47

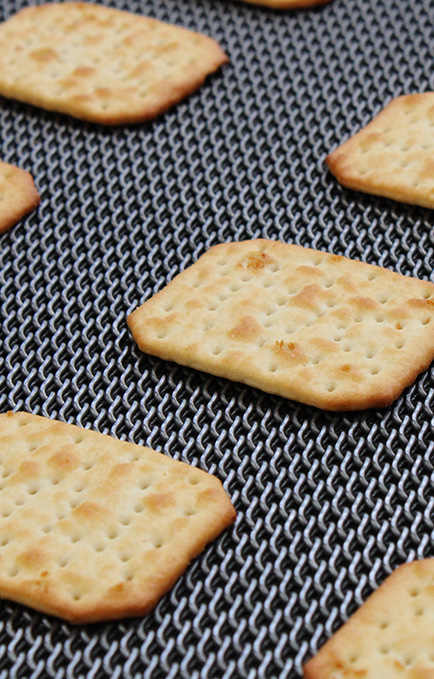

the belt renowned for large, high-performance equipment. (speed up to 30m/min). The space between the meshes allows excellent air circulation during cooking.

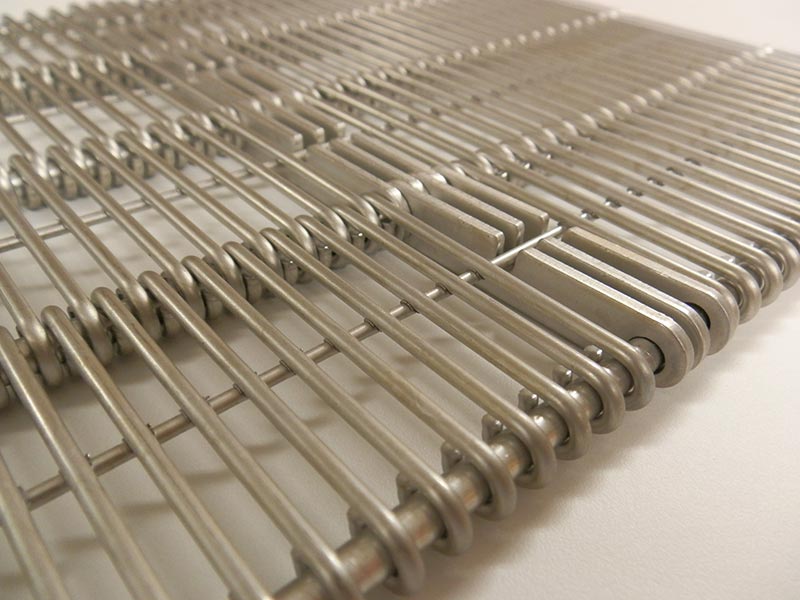

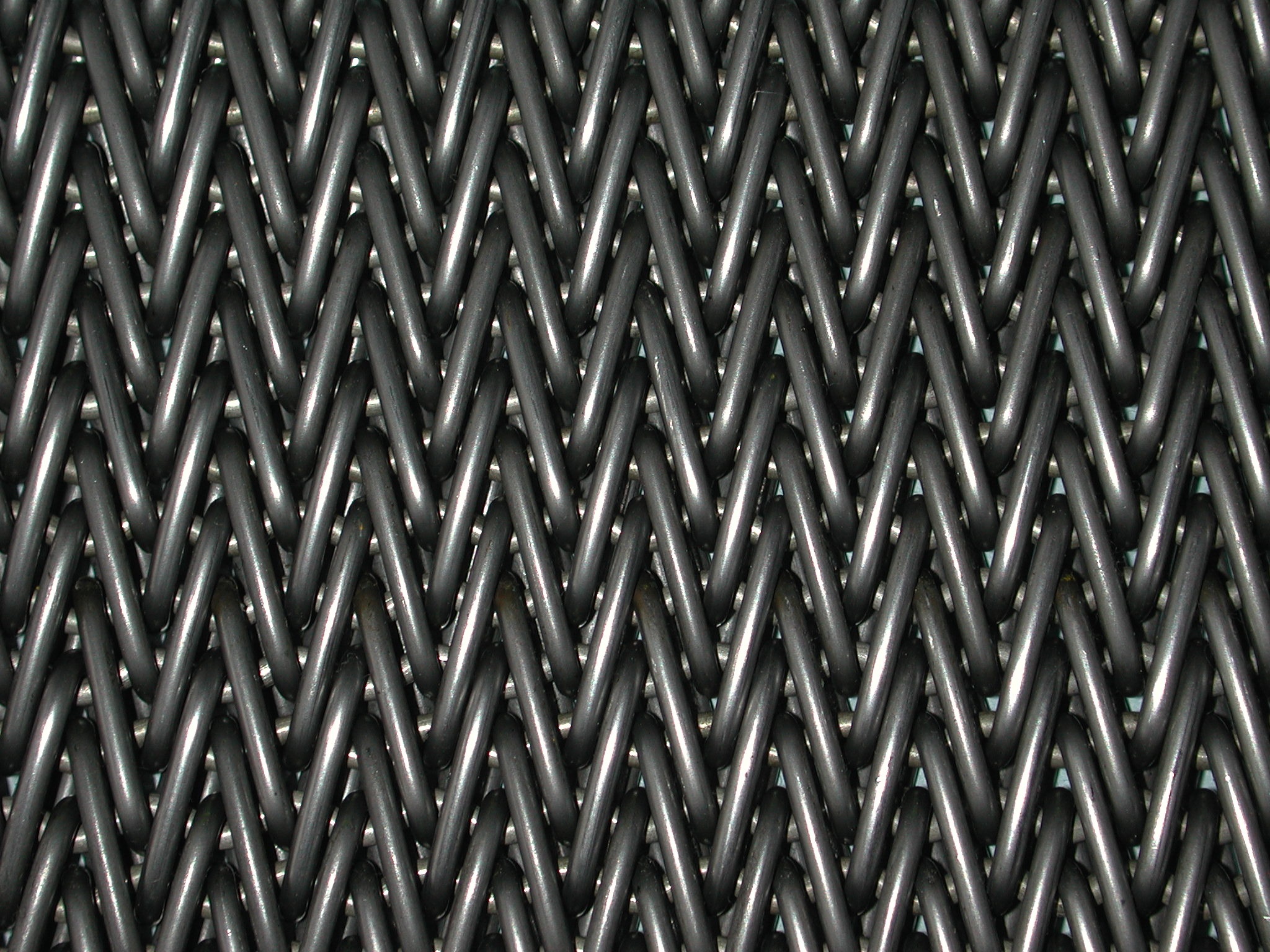

Z47R

is a version of the Z47 belt with increased resistance to tearing, for a longer belt life or intensive use.

However, its use requires a higher cooking temperature than with the Z47.

RANGE OF PRODUCTS

Today, metal belts for ovens are delivered to biscuit factories all over the world, directly from the Savoie factory or through a network of approved distributors.

Z47

the belt renowned for large, high-performance equipment. (speed up to 30m/min). The space between the meshes allows excellent air circulation during cooking.

Z47R

is a version of the Z47 belt with increased resistance to tearing, for a longer belt life or intensive use.

However, its use requires a higher cooking temperature than with the Z47.

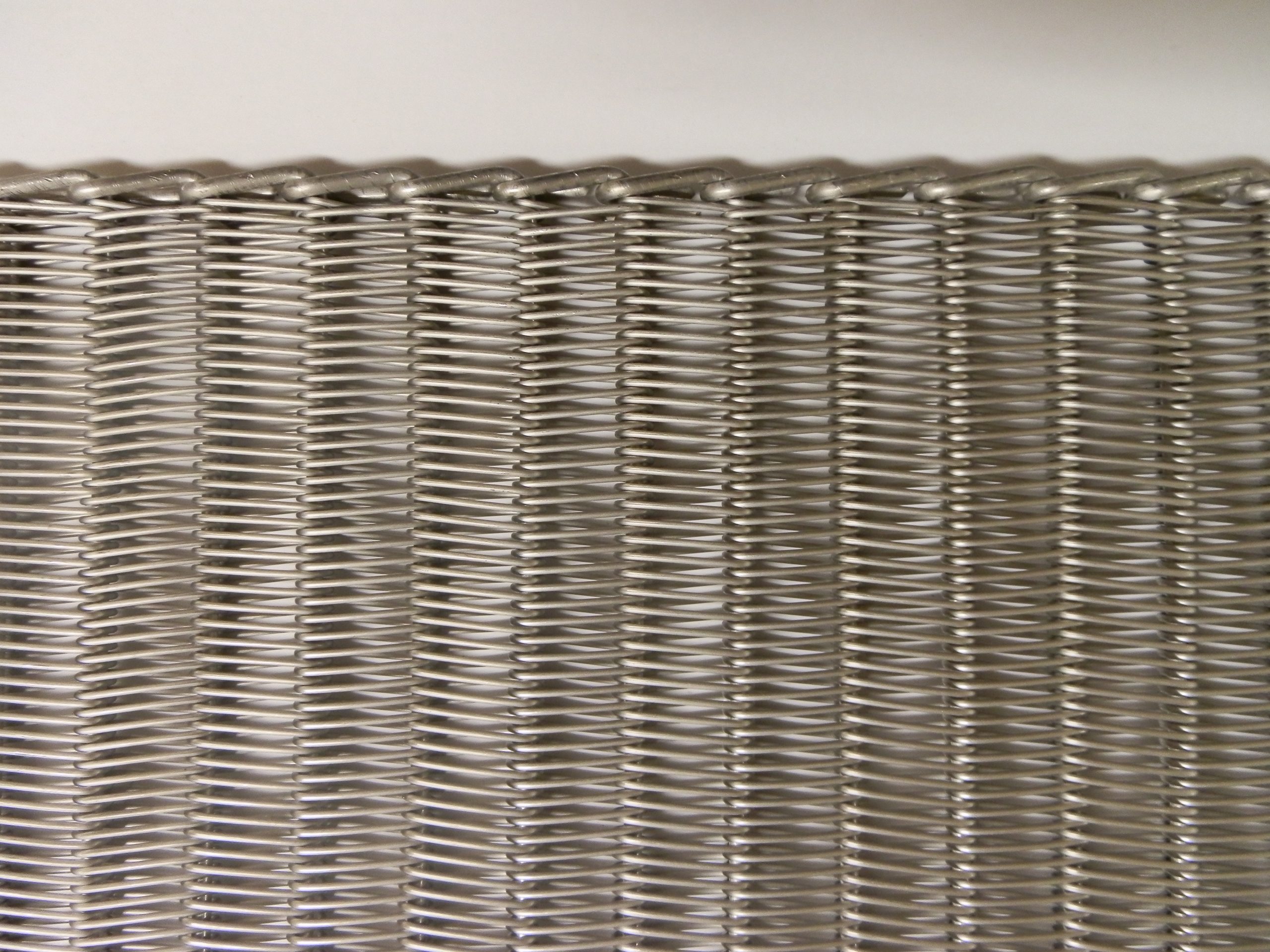

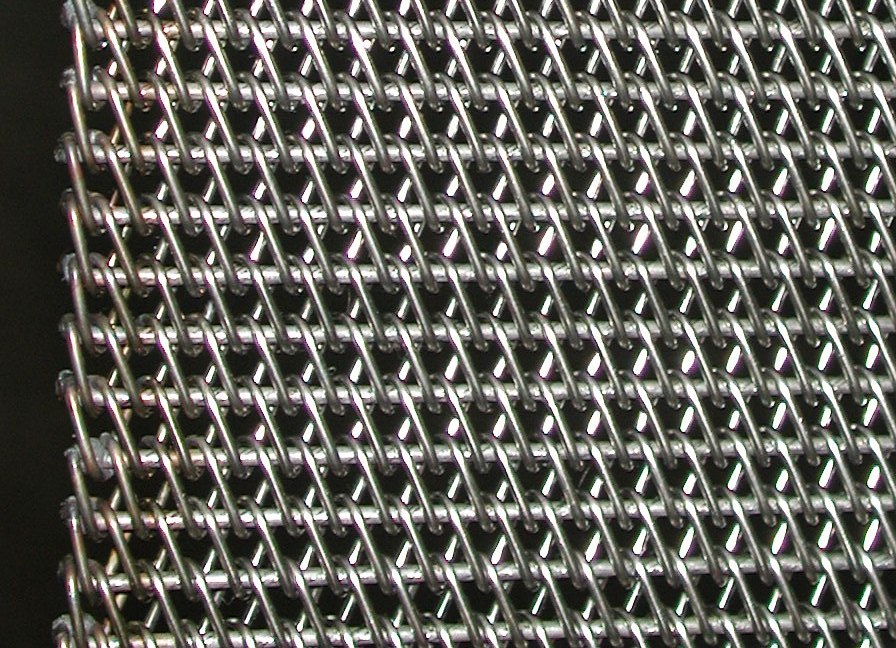

Z28

allows the oven temperature to be lowered, for the purpose of savings. The wire diameter is smaller, and high temperatures should therefore be avoided.

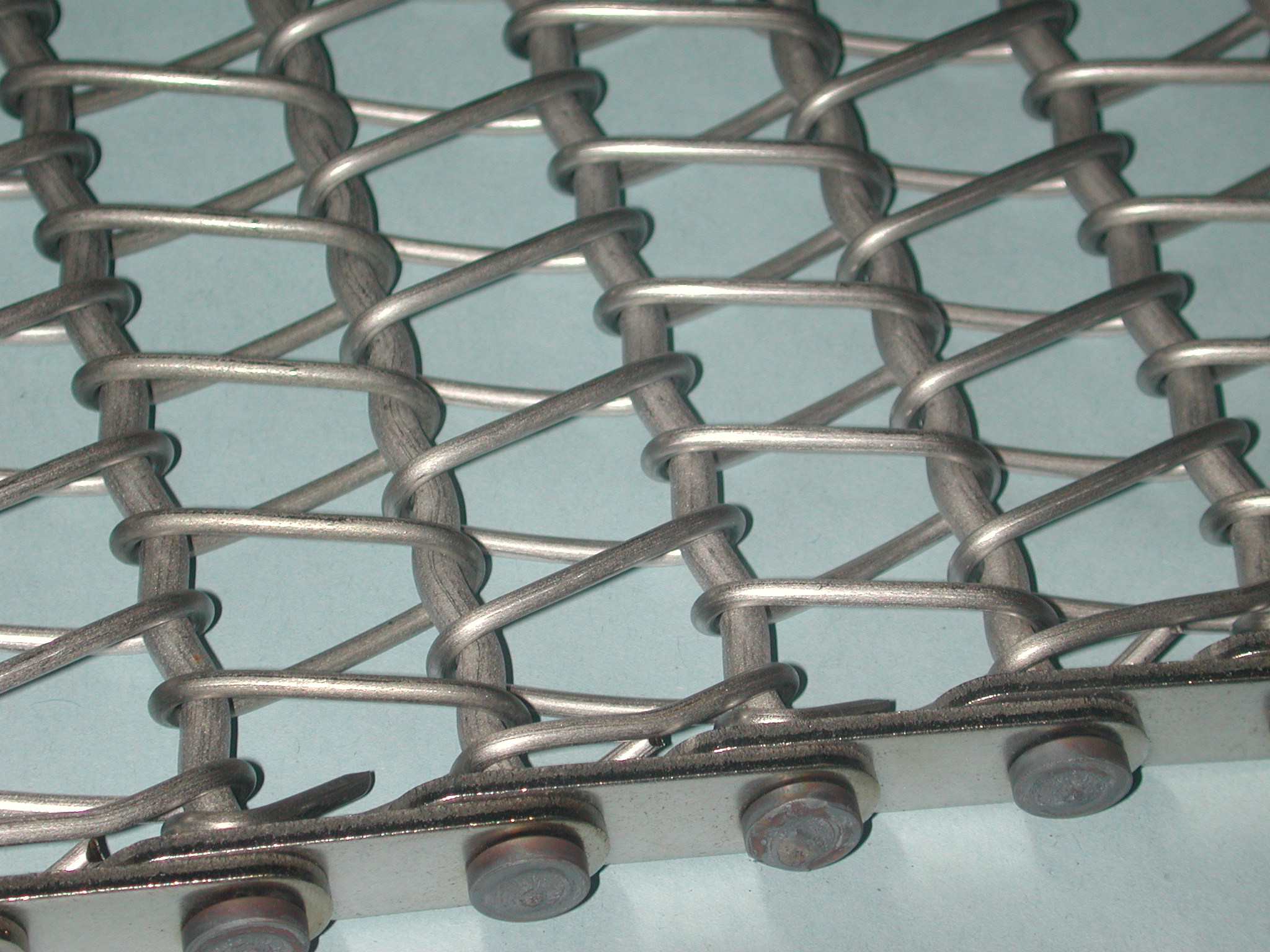

Z48

specially designed for baking rusks and hard biscuits, the Z48 belt has wide mesh for optimised air circulation.

CHARACTERISTICS OF THE BELTS

We mainly offer 4 types of Z belts depending on the technical characteristics required:

Weight, size, thickness, thermal inertia, air circulation through the mesh.

All Z belts are made following strict quality criteria. The edges are looped to make the belt more flexible and improve contact with the drive drums, even those with small diameters. The finishing of the edgers reduces the risk of damage to the belt by the lateral guides or the blades of the ovens.

The manufacturing method ensures perfect alignment of the wire and a wider space between the meshes for equivalent resistance. This is essential for allowing our clients to quickly and evenly cook in their ovens, while keeping the Z belt clean.

Looped edges (thickness +8/10mm)

• Increase the lifespan of the edges (more resistant to friction)

• Prevent vibrations when in contact with other metal parts

• Protect operators during handling

TECHNICAL DATA (DIMENSIONS)

Start-up

Before starting the conveyor, cut the Z belt to the correct dimensions, leaving sufficient travel for the drive drum. The tension of the Z belt must be sufficient to prevent the belt from slipping off the drive drum. Please check the rotation direction (see painted arrow).

Recommendations

It is recommended to change the belt every 3 years when used in normal production. In case of more intensive use or ovens at very high temperatures, the lifespan is significantly reduced.

It is important to note that each belt is produced according to the client’s needs (in particular the width and length). The normal delivery time is therefore between 6 and 10 weeks. It must therefore be included in preventive maintenance.

OTHER PRODUCTS

La Bridoire Belts is an expert in the production of its product: ‘Z-bands’. But our company also offers other types of metal belts.

Let’s discover all our products.

OUR CLIENTS

Clients all around the world

We commercialise our metal Z belts for ovens in France and internationally. With our experience and knowledge, we have been producing metal mesh for almost 100 years. Our design is carried out in France, specifically in Savoie.

Clients all around the world

We commercialise our metal Z belts for ovens in France and internationally. With our experience and knowledge, we have been producing metal mesh for almost 100 years. Our design is carried out in France, specifically in Savoie.